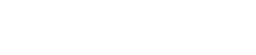

If you’re a stone fabricator still shying away from mitered edge countertops, you’re not alone. Getting a good miter cut is no easy task. These are the two biggest issues fabricators face with mitered edge countertops, and the solution to make miter cuts fast, easy, and flawless!

The Issues

The Solution

|

What is a miter workstation?

A Miter Workstation is a stone rail saw with everything you need to cut perfect miters. That includes a heavy-duty specialized blade, stainless steel tracks, and mitering attachments. Everything is quick to assemble and use on its working table.

You can try jerry-rigging your own miter workstation, or you can let us do the work for you. We’ve designed the only miter workstation out there.

Higher Production: With a dedicated miter workstation, you’ll get a few extra slabs cut up every day. No second-shifts or OT.

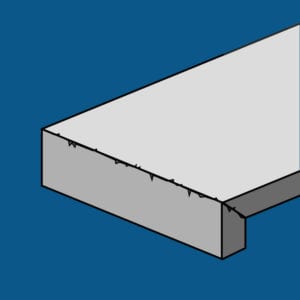

Higher Quality: Cuts are MUCH cleaner. Clean, super sharp miter cuts that are straight! And no chips!

Versatility: You can use your miter workstation a backup saw or overflow saw.

More Materials: You’ll be able to cut even the most difficult materials. Check out the video below to see these cuts on Rainforest Brown stone, which is notorious for chipping.

View the full product details of our miter workstation here: https://accuglidesaws.com/accuglide-miter-cutting-station

With these tips, the right tools, and perhaps a miter cutting workstation of your own, you’ll be producing high quality mitered edge countertops that may be your most profitable work yet!